I. Introduction

Laboratories worldwide rely on acids such as hydrochloric acid, sulfuric acid, nitric acid, and hydrofluoric acid for routine work. Despite their utility, these chemicals present major health and environmental hazards unless managed carefully under globally harmonised frameworks such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and region-specific regulations. The objective of this article is to align laboratory acid safety practice with international criteria and provide actionable guidance.

II. Chemical Properties and Classification

1. Hydrochloric Acid (HCl): A colourless to slightly yellow liquid, strong irritant vapour, highly corrosive to metals and tissue. Under GHS, it typically falls into Skin Corrosion Category 1 and Eye Damage Category 1.

2. Sulfuric Acid (H₂SO₄): Dense, oil-like liquid, no odour, with strong dehydration capability; it can instantly char organic matter. Its pH and reactivity place it in extreme corrosivity profiles under international classification.

3. Nitric Acid (HNO₃): Colourless or faint yellow liquid which darkens due to NO₂ formation; strong oxidising acid reacting vigorously with metals and organics. Under GHS, it is both corrosive and an oxidizer (Oxidising Liquid Category 1).

4. Hydrofluoric Acid (HF): A fuming, colourless liquid; uniquely hazardous because fluoride ions deeply penetrate tissue, bind calcium/magnesium, and cause deep systemic toxicity beyond simple burn.

III. Hazard Analysis & International Safety Frameworks

International safety frameworks emphasise that hazard classification is the starting point of risk management. According to the GHS, chemicals are classified based on intrinsic properties (not exposure scenarios).

1. Shared hazards of these acids include:

Corrosivity: Skin contact may lead to irreversible damage; eye contact may cause permanent blindness.

Inhalation: Acid mists/vapours may cause chemical bronchitis, pulmonary oedema; inhalation classification falls under acute toxicity categories.

Reactive/oxidising hazard: Particularly for nitric acid, classification under the Oxidising Liquids Category 1 mandates extra controls.

2. Unique hazards:

HCl: volatile – risk of acid mist inhalation and rapid respiratory tract damage.

H₂SO₄: dehydration effect + risk of violent reaction when diluting (must follow “acid into water slowly” rule).

HNO₃: strong oxidising nature causes skin bleaching, yellow stains (protein oxidation reaction), and NO₂ gas hazard.

HF: Deep tissue penetration, binding to Ca²⁺/Mg²⁺ leading to hypocalcaemia, arrhythmia, bone decalcification; even low-concentration exposures are dangerous.

IV. Protection, Storage & Emergency Response

1. Protection & Operation Practices:

Use an acid-resistant lab coat, nitrile or neoprene gloves, safety goggles, or a face shield.

Conduct all acid operations inside a functioning fume hood or local exhaust system.

Labels must comply with GHS: include signal word (“Danger”), hazard pictograms (e.g., corrosive symbol, oxidiser symbol), and precautionary statements.

For sulfuric acid dilution: Always add acid into water slowly along the vessel wall while stirring — never add water to acid.

2. Storage & Inventory:

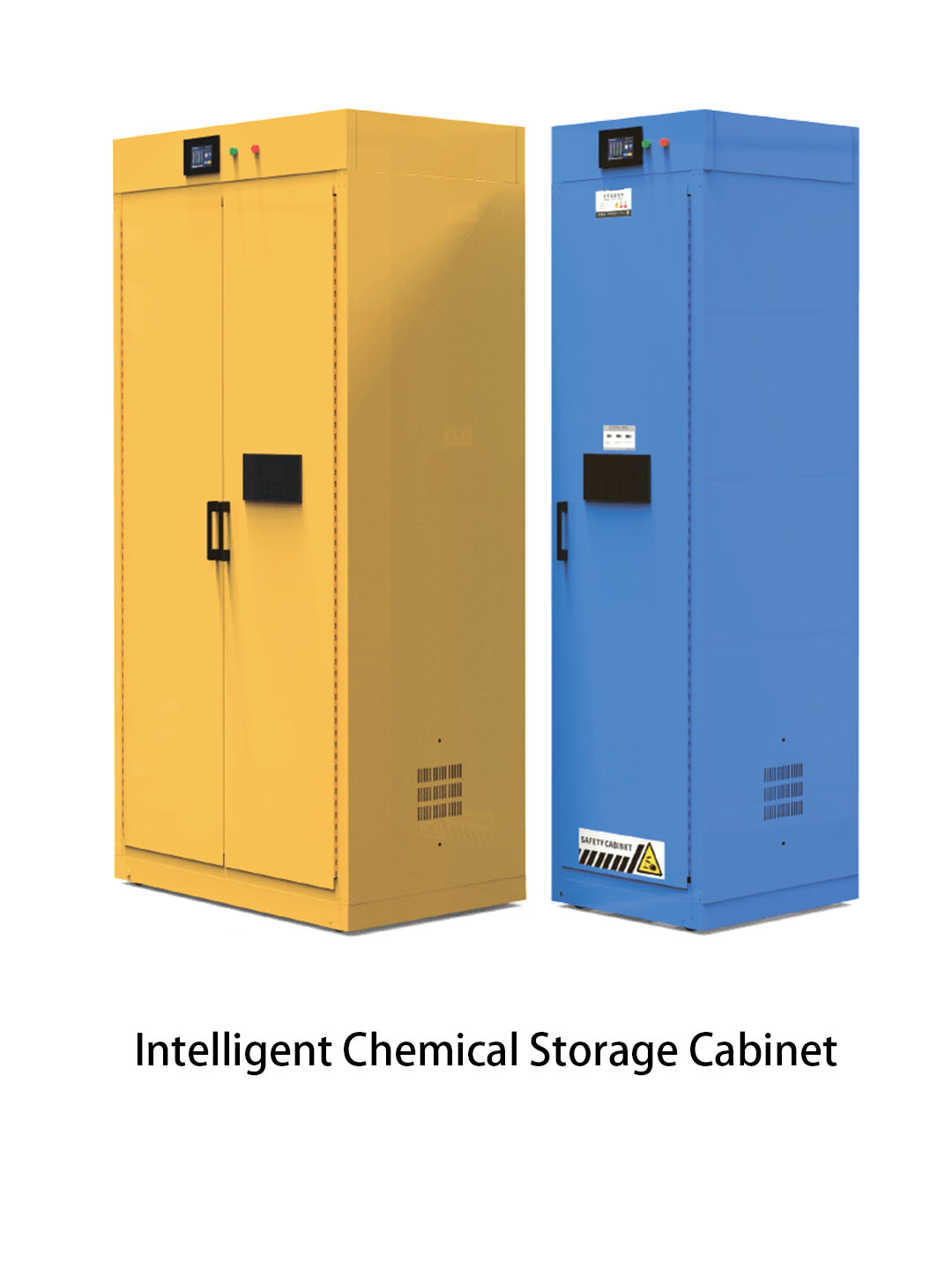

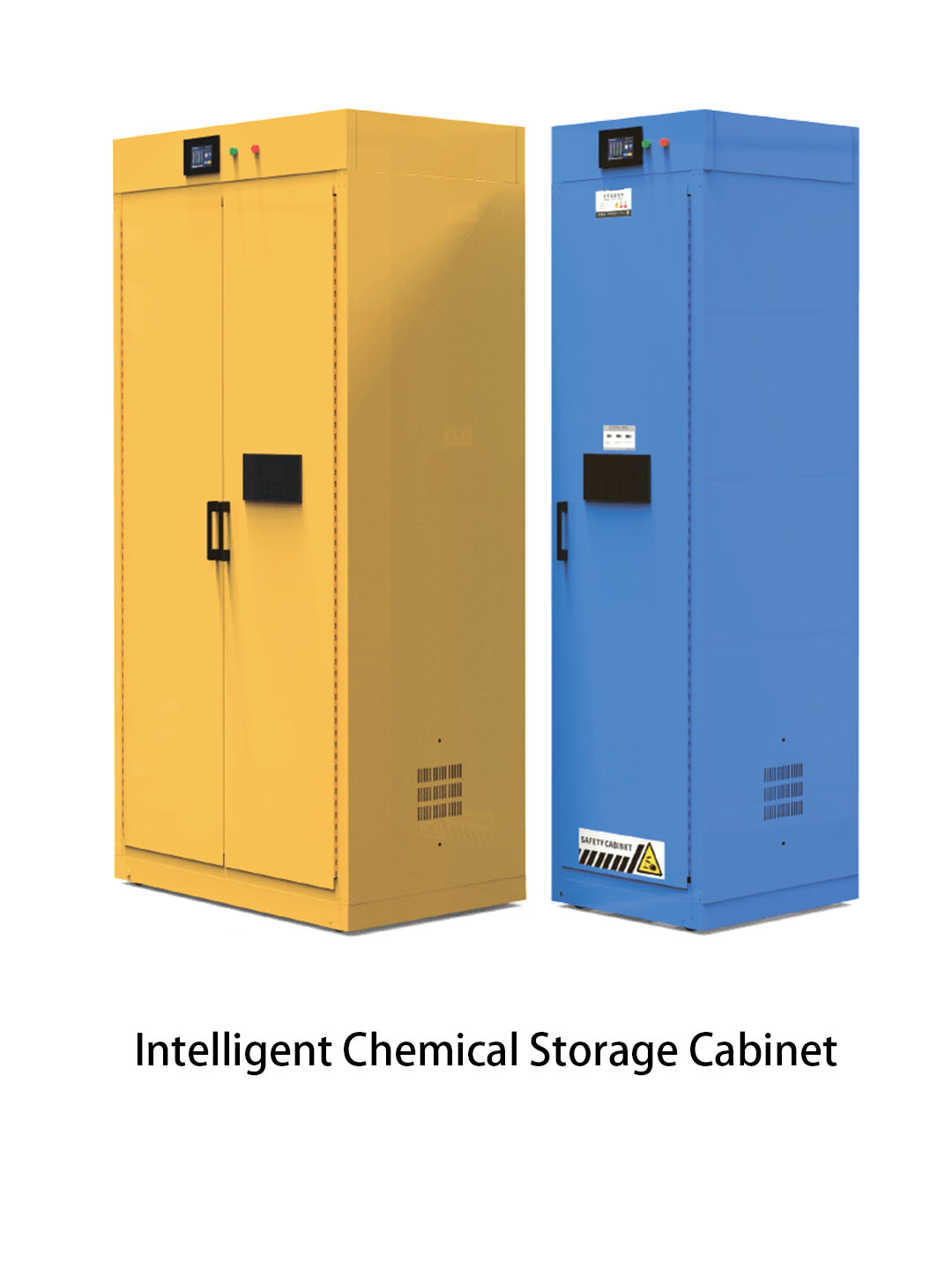

Under international chemical-safety guidelines (e.g., Organisation for the Prohibition of Chemical Weapons OPCW Indicative Guidelines), allocate dedicated lockable cabinets, segregate incompatible materials (acids away from bases, organics, oxidisers), maintain inventory logs, ensure ventilation, and maintain cool conditions.

Waste acid solutions must be collected in clearly labelled containers and disposed of via licensed hazardous waste channels.

3. Emergency Response:

Skin contact: Remove contaminated clothing, flush affected area with copious flowing water for at least 15-30 minutes; for HF exposure, calcium-gluconate gel may be applied, and immediate medical attention is critical.

Eye contact: Hold eyelids apart, flush continuously with water or saline for ≥15 minutes, then seek urgent medical care.

Inhalation: Move the victim to fresh air, maintain calm, and seek medical attention.

Ingestion: Do not induce vomiting; call emergency services and provide SDS information.

After initial first aid, a medical evaluation is mandatory.

V. Conclusion

Adhering to globally harmonised chemical safety systems — such as GHS for hazard classification and OPCW guidelines for safe storage and handling — laboratories can significantly reduce the risk posed by corrosive acids. By combining rigorous protective equipment, operational discipline, inventory supervision, and decisive emergency response, research institutions align themselves not just with regulations but with a culture of safety.

VI. References

1. United Nations Economic Commission for Europe. Globally Harmonized System of Classification and Labelling of Chemicals (GHS) Rev. 10. Geneva: UNECE, 2023.

2. Bajraktarova-Valjakova E., Korunoska-Stevkovska V., Georgieva S. et al. “Hydrofluoric Acid: Burns and Systemic Toxicity, Protective Measures and Clinical Management.” Open Access (2018).

3. Dennerlein K. “Dermal absorption and skin damage following hydrofluoric acid contact.” Toxicology (2016).

4. U.S. Environmental Protection Agency. “Chemical Hazard Classification and Labeling (GHS criteria summary).” (2004).

5. Occupational Safety and Health Administration (OSHA). “Hazard Classification Guidance for Manufacturers, Importers, and Employers.” Washington DC.

6. Acknowledgement: Part of the content and structure of this article refers to publicly available materials from the WeChat Official Account of the Laboratory Safety Office, University of Science and Technology of China (USTC).https://mp.weixin.qq.com/s/5uPMT48KmHRSv0lpFoWmDA